So, what are bagpipes made of?

Scots love their clan gatherings, which is a significant gathering that allows them to meet others in their family and celebrate their Scottish heritage.

Many states in the United States, including Michigan and New York, have large populations of Scottish or Scotch-Irish that offer “Highland Games,” including sports like tossing the cover where men toss heavy poles to see who can throw the farthest.

In addition to this, bagpipes are often included as a part of this celebration.

North Carolina has one of the most significant populations of Scottish descent and hosts the largest gathering each July at Grandfather Mountain.

Here, MacGregors, Andersons, and Campbells mingle while enjoying traditional Scottish cuisine and Scotch whiskey.

Before You Continue Reading…

Check out these useful bagpipe resources:

Last update on 2024-04-17 / Affiliate links / Images from Amazon Product Advertising API

Contents:

What Are Bagpipes Made Of?

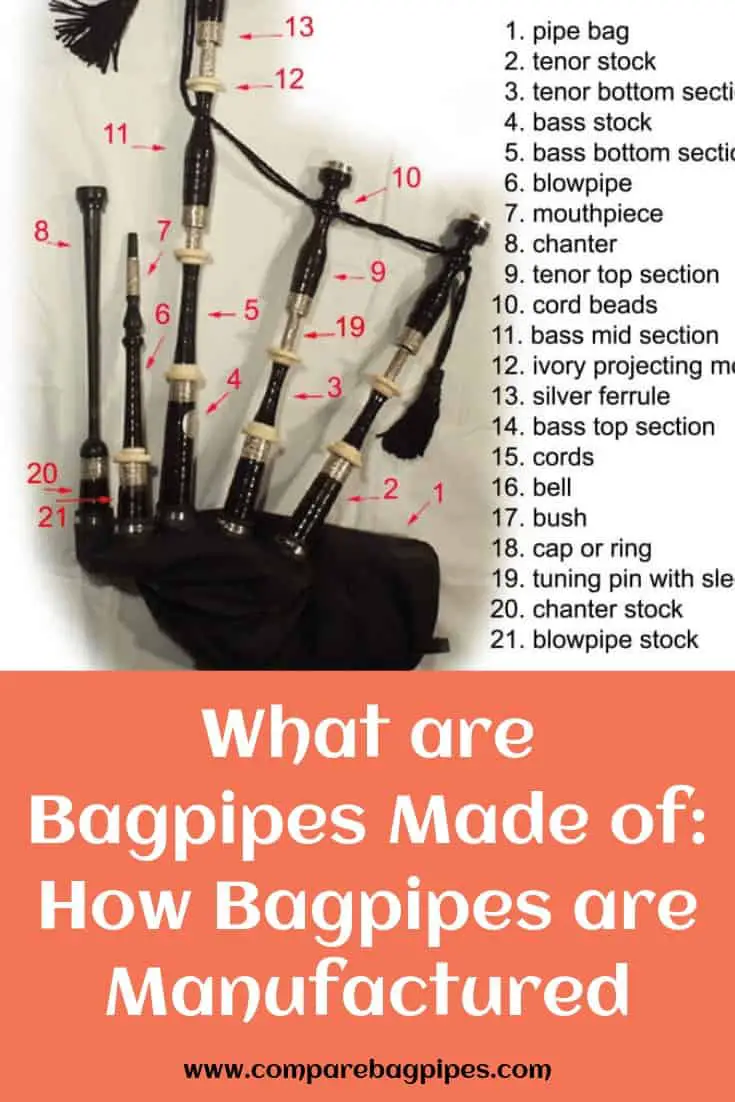

1. The Wood Drones And The Chanter

The chanter and drones are made from imported African Blackwood by a pipe maker.

The African Blackwood is then sliced into planks and then further cut into squares, air-dried for three to seven years.

Some manufacturers are using kiln-drying to speed up drying times and the expense associated with long drying times.

Once the moisture is reduced in the wood and the pipe maker deems it is suitable for working, the pipe maker uses a gun drill, a reamer, a twist drill, or a single flute drill to bore out the cylindrical drones.

Most pipe makers prefer a single flute drill because it makes the cleanest bore.

However, a carbide-tipped gun drill uses a coolant hole to blow fluid or air into the bore to help clean out wood chips.

After this, the outside shape of each drone is finished using a lathe.

The ferrules, which are metal tips and bands that protect the drones, are either glued or press-fit into place; finally, the pipe maker threads on the projecting mounts.

The last step involves applying a varnish, wax, lacquer, or oil to treat the wood.

The finish will be based on the type of wood used, the humidity, and the pipe maker’s own preferences and style.

The chanter is produced like the drones are, with two exceptions.

First, the chanter has a cone shape, which means it is step-drilled using twist drills and then enlarged using a single flute reamer that is 33 cm (13 in) long.

The narrow end of the reamer’s diameter is approximately 0.32 cm (0.13 in); the larger end of the reamer’s diameter is 2.22 cm (0.87 in).

The chanter must be bored correctly as it determines the tone of the chanter.

The second process is the milling or drilling of the finger holes once the bore has been turned.

Once the finger holes are drilled, the surface is finished to match the drones of the bagpipe.

The stocks are made similarly to the wood pipes.

They are made using straight holes with tie-in groves located along the bottom.

The stocks must be long enough to accommodate the drones’ reeds.

Each stock contains a ferrule at the top to help prevent the stock from splitting.

2. The Bag

The bagpipe bag is typically made from either cowhide or elk hide; usually, four to five bags can be made from a piece of cowhide.

The hide is folded in half, and the bag sides are cut at once to ensure a mirror image.

The pipe maker then uses contact adhesive to temporarily hold the bag together until a leather welt can be made and put into place; then, the welt and the seams are stitched together.

The pipe maker hand stitches the seam and welts using double needs; it takes approximately two hours to stitch a single bag.

3. Assembling The Bagpipe

The Great Highland bagpipe contains fourteen pieces that are tied together. The five stocks are tied using nylon, hemp, or waxed linen.

Certain pipe makers use corked joints like those used in clarinets; however, they are not as popular as other methods.

The chanter and the drones are then connected to the stocks; the only thing remaining is to add the reeds to the pipes.

The final step involves sanding the wood pipes; the pipe maker smooths the surface with 80 to 120 grit sandpaper and works up to 400 grit sandpaper for a smooth finish.

Finally, the pipe makers apply heated wax or oil by hand using a fine cloth.

If the pipe maker prefers varnishing or lacquering the pipe, he will use 220 grit sandpaper to smooth the wood before applying the varnish or lacquer with a camel hairbrush.

If the maker prefers, the varnish or lacquer can be sprayed on using a paint booth.

4. Reeds

The reeds are handmade from a water reed or a piece of metal tubing.

The chanter requires a double reed that is fashioned from a brass or copper tube.

The tubes can be either conical or cylindrical.

Two slices of reed are then placed against the tube and wrapped into place.

Reeds for drones use tubular lengths of reed or cane rather than slices.

Nodes on the cane mark the location where the leaves were located while the reed was alive.

Above each node on the cane, the pipe maker makes a cross-cut slice and two parallel cuts that are perpendicular to the slice.

The small tongue made by these three cuts is raised the node to form a brace for its base.

The tongue is approximately one-quarter to one-half the diameter of the reed or cane.

As air passes through this cut, the tongue will vibrate and produce a tone.

The opposite end of the reed or cane is tapered and attached to the drone.

If the pipe maker uses modern materials, a plastic tube is used in place of the drone reed, and a separate piece of plastic is used for the tongue.

Once the reeds are inserted into the pipes, the bagpipe is complete.

Waste And Byproducts Of Bagpipe Production

Dust from the wood used for bagpipe production is toxic.

Therefore, the pipe maker must wear protective gear, including a respirator, to avoid inhaling the wood dust – a dust mask does not offer enough protection.

Most of the products used in bagpipes are biodegradable.

The plastic waste is minuscule and typically disposed of in a landfill.

Thinners and organic compounds like lacquer and varnish are used.

However, these are typically stored in small quantities to minimize waste.

The primary hazard associated with the manufacture of bagpipes is dust.

Thus, the pipe maker must wear protection, including hearing protection, because of the noisy tools used in production.

Quality Control Methods

One of the most significant issues when it comes to the manufacture of bagpipes is quality control.

The pipe maker crafts each bagpipe and must monitor his work throughout the production process.

The tolerances are so minimal in boring and turning pipes because they can affect the pitch and sound produced.

The internal dimension can only vary by plus or minus 0.013 mm (0.0005 in) before the sound is affected.

The exterior diameter can vary up to 0.25 mm (0.1 in).

The tolerances are the most common issue affecting the production of a quality bagpipe.

The pipe maker’s reputation relies on his ability to create bagpipes that look the same, and more importantly, sound the same.

The Future Of Bagpipes

Interest in bagpipes continues to grow steadily in both Canada and the United States.

These are the two largest bagpipe markets in the world.

The demand has remained steady for several years.

However, the number of people playing the bagpipes is growing.

Mark Cushing, a master pipe maker, credits the increased interest to two things.

People who research their family history are drawn to learning how to play bagpipes.

Additionally, the sound and emotions that bagpipes create attract more people to learning how to play the bagpipes.

No matter why people want to learn to play the bagpipes, pipe band associations across the United States and Canada encourage others to learn to play the bagpipes by providing lessons.

Thanks to the love of bagpipes by citizens worldwide, pipe makers anticipate a long-lasting future for the artistry of bagpipe production.

FAQs

It depends on the location of manufacturing!

But generally, the modern manufacturers use tropical hardwood to make their bagpipe instruments.

Some manufacturers also use plastic for the production of bagpipes these days.

As per the history records, the Bagpipes seem to have originated in the Middle East region.

Since there are many different varieties of this instrument, it’d be difficult to classify it under one particular category.

Still, if you want to learn more about it, check out this guide on the difference between Irish and Scottish bagpipes.

Around 16th Century, the tradition of wearing kilts began in Scotland and nearby regions.